|

IB Business Management:

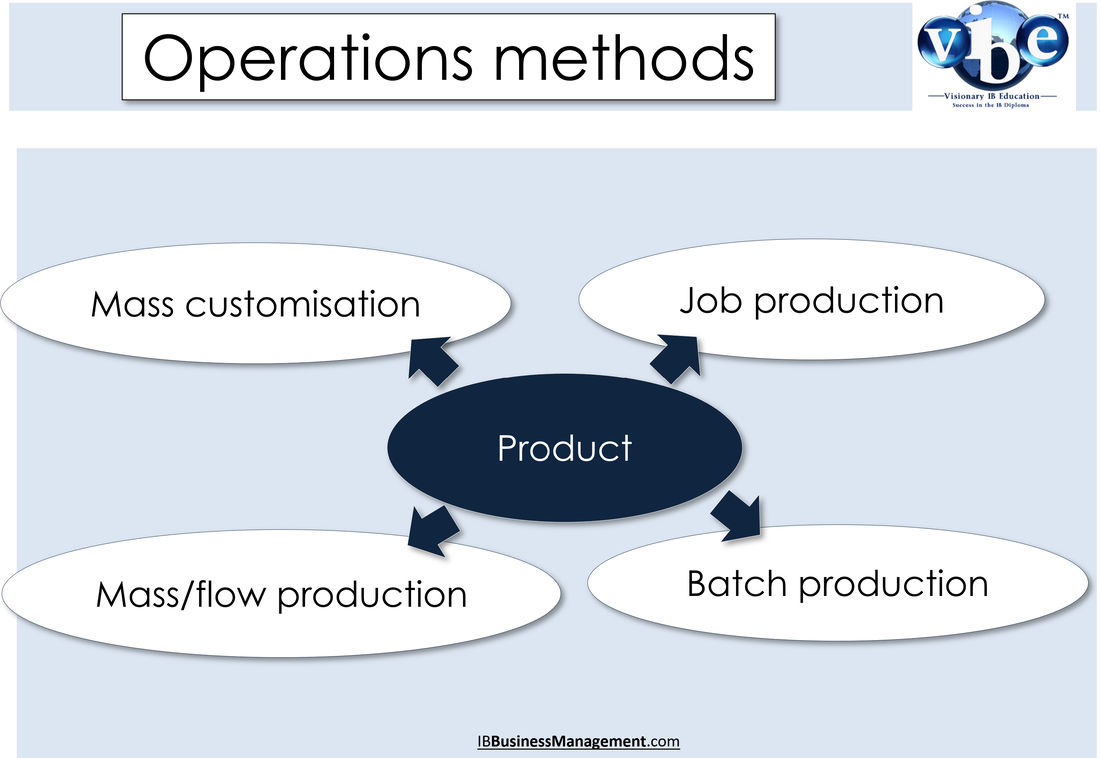

5.1 Operations methods The different operations methods in the IB Business Management course fall into three main categories: job (one-off production), batch (multiple items, one step at a time for all items), and flow (multiple items, all steps in process at once for separate items).

|

|

Key learning outcomes:

|

The role of operations managementOperations management is a critical function in any organisation, whether it's a manufacturing firm, a service provider, or a non-profit entity. It is the process of planning, organizing, directing, and controlling the resources, processes, and systems involved in the production and delivery of goods and services. The primary goal of operations management is to ensure that an organisation operates efficiently, effectively, and meets the needs of its customers while maintaining a sustainable competitive advantage. The role of operations management can be broken down into several key areas:

|

Operations management explained

In summary, the role of operations management is to ensure that an organisation operates efficiently and effectively, delivers high-quality products and services, and remains competitive in the marketplace. This involves managing resources, processes, and systems, as well as working closely with other business functions to achieve organisational goals. |

Operations methodsThere are several different ways in which goods and services can be produced. These production methods fall into three main categories: job (one-off production), batch (multiple items, one step at a time for all items), and flow (multiple items, all steps in process at once for separate items).

There are four different classifications of operations methods :

|

Operations – economies of scaleNo one does mass production quite like the Chinese. Economies of scale that will take your breath away! This video is fantastic. Don't wait for anything to happen, don't wait for anything to be said. Just sit back, enjoy and be prepared to be astonished as every passing second reveals more and more of the staggering size of this operation. This one factory is responsible for 99 per cent of worldwide iron production (that's iron as in 'ironing one's clothes').

|

Key termsJob production: Job production is the manufacture of individual 'one-off' or unique items made to customer specifications. The product is seen through the whole process, from start to finish, by an individual or group of workers. The production of the next individual item does not begin until the previous job is complete.

Batch production: is where the manufacturing process is split into a number of different operations; each of which is carried out on the whole batch before it is moved on and another batch received. The batch is moved on from one stage of production to the next until all the manufacturing processes are completed. Batch production involves the manufacture of a group of identical items and is normally used when the demand for the product is relatively constant. Flow/flow production: A production method where all the different operations required for production are carried out in a sequence one after the other. It is usually used where mass production is required to meet high levels of demand and when the product being manufactured is reasonably standardised. Mass customisation: The use of flexible computer-aided production systems to produce items that meet individual customer requirements at mass production cost levels. Such manufacturing systems combine the low unit costs of mass production processes with the flexibility of individual customisation. |

Job productionJob production is normally used for the production of single one-off products. The products may be small or large and are often unique. In order to be called job production, each individual product has to be completed before the next product is started. At any one time, there is only one product being made. New, small firms often use labour-intensive job production, before they get the chance to expand and purchase advanced equipment. Job production enables specialised products to be produced and tends to be motivating for workers because they produce the whole product and take pride in it.

However, this production method tends to result in high unit costs, often takes a long time to complete, and is usually labour intensive. The labour force also needs to be highly skilled and this is not always easy to achieve. Watch the video of a master watch maker producing a bespoke watch to get some idea of why these watches are so expensive. Aston Martin is an example of a very expensive car that is individually produced for the needs of each customer. Each engine is hand built and carries a plate with the engineers name on it. |

Producing bespoke watchesProducing an aeroplane |

Batch productionBatch production makes products in separate groups and the products in each batch go through the whole process together. The production process involves a number of distinct stages and the defining feature of batch production is that every unit in the batch must go through an individual production stage before the batch as a whole moves on to the next stage.

Batch production allows firms to use division of labour in the production process and it enables economies of scale if the batch is large enough. It is usually employed in industries where demand is for batches of identical products (say, raspberry doughnuts) . It also allows each individual batch to be specifically matched to the demand, and the design and composition of batches can easily be altered (to say, chocolate doughnuts). The drawbacks are that batch production tends to have high levels of work-in-progress stocks at each stage of the production process The work may well be boring and demotivating for workers. If batches are small, then unit costs are likely to remain high. There is often a need to clean and adjust machinery after each batch has passed through. |

Batch production: hotdogsBatch production: bubblegum |

Mass/flow productionThis method is used when individual products move from stage to stage of the production process as soon as they are ready, without having to wait for any other products. Flow production systems are capable of producing large quantities of output in a relatively short time and so it suits industries where demand for a product is high and consistent. It also suits the production of large numbers of a standardised item that only requires minimal alterations. This is often why it is often referred to as mass production. Flow production usually takes place on a production line – hence the use of the term production line.

Flow production has a number of advantages over other types of production. Labour costs tend to be relatively low, because much of the process is mechanised and there is little physical handling of products. The constant output should make the planning of inputs relatively simple and this can lead to the minimisation of input stocks through the use of just-in-time (JIT) stock control (a 5.6 Production Planning topic). Quality tends to be consistent and high and it is easy to check the quality of products at various points throughout the process. The main disadvantage is the high initial set-up cost. By definition, capital intensive, high technology production lines are going to cost a great deal of money. In addition, the work involved tends to be boring, demotivating and repetitive. |

A funny example of mass/flow production!Beer bottling example of mass/flow production |

Mass customisationThe search for production methods that combine the advantages of job production – flexibility and worker satisfaction – with the gains from flow/mass production – low unit costs – has lead to the development of mass customisation where custom output can be produced.

This method is only possible because of tremendous advances in technology such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These have allowed much quicker development of new product designs that feature many common components and robotic machinery that can be switched to making different parts. (The Tesla factory video illustrates this perfectly.) The mass customisation process combines the latest technology with multi-skilled labour forces to use production lines to make a range of varied products. This allows businesses to move away from a mass marketing approach with high output of identical products. Instead, differentiated marketing can be used which allows for higher added value – an essential objective of all operations managers. |

Mass customisation at the Tesla factoryThe future of manufacturing: Industry 4.0 |

Student focus question:

|

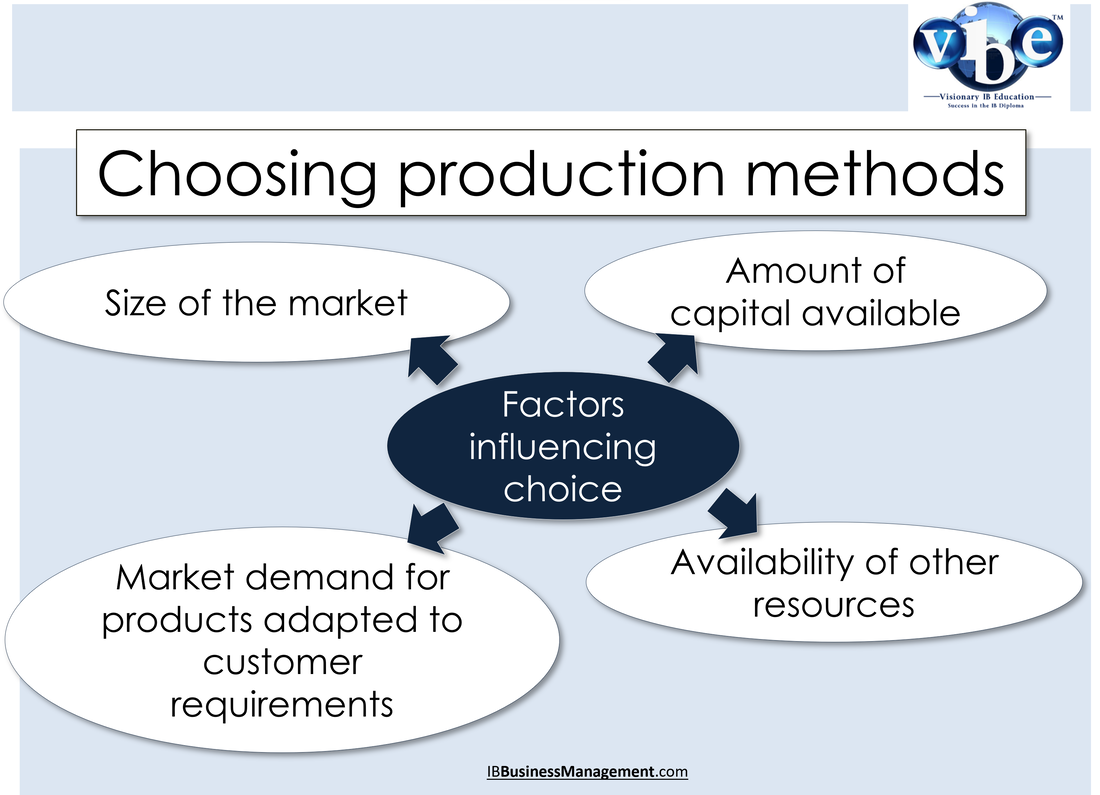

Choosing the right production methodThe following factors will influence whether a business adopts one of the four methods of the different production methods examined here.

Impact of changing production methods

Your browser does not support viewing this document. Click here to download the document.

|

IB Business Management 5.1 Operation methods

SUMMARY NOTES

IB Business Management: 5.1 Operations Methods teaching and learning PowerPoint notes for HL and SL IB Business Management

PROGRESS CHECK – Test your understanding by completing the activities below

You have a range of practice activities, interactive flash cards, exam practice questions, interactive quizzes and classroom games to ensure you and your students have complete mastery of the IB Business Management requirements for the 5.1 Operations Methods topic.

USE THE FLASHCARDS IN ALL STUDY MODES

|

IB Business Management

5.1 Operations methods Student learning activity A

Your browser does not support viewing this document. Click here to download the document.

|

IB Business Management

5.1 Operations methods Student learning activity B

Your browser does not support viewing this document. Click here to download the document.

|

|

IB Business Management

5.1 Operations methods Student learning activity C

Your browser does not support viewing this document. Click here to download the document.

|

IB Business Management

5.1 Operations methods Exam practice questions

Your browser does not support viewing this document. Click here to download the document.

|

IB Business Management interactive quizzes and classroom games

Test how well you know the IB Business Management Operations: 5.1 Operations Methods topic with the interactive self-assessment quizzes below. Each interactive quiz selects 30 questions at random from a larger question bank so keep on practicing! Aim for a score of at least 80 percent.

|

Loading 5.1A Operations Methods

|

Loading 5.1B Operations Methods

|